Which Dozer Blade Is Right for You?

Your bulldozer blade is the key component in the heavy lifting and moving of your material, so knowing which blade is best suited to your task, will save you time and consequently, money.

Wheel dozers, crawler dozers, and mini dozers are three of the most common bulldozers available. They can all be further categorised by the blade attachment they carry. Blade attachments are multifunctioning, however, depending on project specifications, it’s important to select the right one, to optimise efficiencies, reduce wear to your equipment and ensure project success.

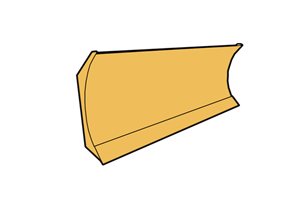

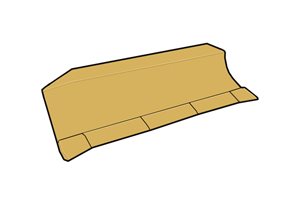

Straight Blades

Typically, the smallest of the bulldozer blade range, the Straight Blade - “S Blade” - is as it sounds; straight edged. The blade attaches at its back-bottom corners and can be set at either a tilt, or flush against the base of the earth.

Due to its shape, this blade is best used when penetrating hard, compact, and sharp surfaces. The lack of wings on its sides, make it a poorer option when dealing with loose materials that can spill out from the blade’s sides.

Use this blade to achieve best results with:

- Ditching

- Stripping

- Back-filling

- Grading

- Shaping

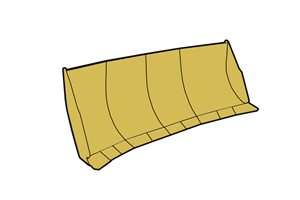

Universal Blades

Unlike the Straight Blade, the Universal “U” Blade, has a curved, bucket-like shape, with wings on each side. This blade also attaches to the dozer, by its bottom-back corners.

Due to its shape and large size, paired with its side wings, the U Blade is regularly used to transport medium-loose materials across a distance.

Use this blade to achieve best results with:

- Ditching

- Loose-load handling

- Crowning

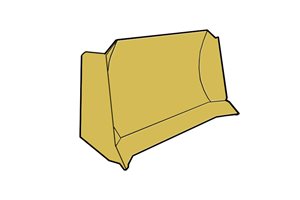

Semi-U Blades

Similarly to the Straight Blade and Universal Blade, the Semi-U “SU” Blade, attaches to the dozer, at the lower-back of the blade. Incorporating elements of both the S Blade and U Blade, it has a straight blade on the base, with curved wings on its edges. The additional curvature of the blade on its edges, allows for the blade to collect and carry more material than the S Blade, and provide more penetrable force than that of the U Blade.

This blade is best used when moving soft to medium materials across long distances, with its carrying capabilities and better penetration abilities than the U Blade. To protect it from wear, it is recommended that this blade is not used directly on hard terrain, without breaking it down first with a ripper.

Use this blade to achieve best results with:

- Ditching

- Stripping

- Levelling

- Crowning

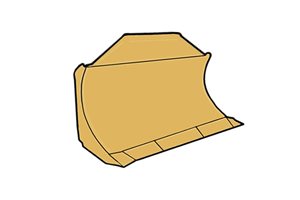

Angle Blades

The Angle Blade attaches at the centre of the blade, differentiating it from previous blades considered. This mounting allows it to be angled at roughly 20-30 degrees left or right, depending on the model. This is achieved by the operator either manually moving the blade or, more commonly in newer models, hydraulically operating it from the cab. Like the Straight Blade, the Angle Blade does not have wings at the edges of the blade, which can result in material spilling out from the sides if loaded too heavily.

The angling ability of the blade and lack of wings, makes it ideal for shifting material off to the side of the dozer, rather than simply pushing it forward. Due to its ability to move up and down, as well as angling left and right, along the tracks, it can be referred to as a ‘4-way’ blade. It is best used when shifting soft to medium, loose material.

Use this blade to achieve best results with:

- Ditching

- Stripping

- Side-casting

- Levelling

Power-Angle-Tilt (PAT) Blade

The Power-Angle-Tilt Blade is much like the Angle Blade but allows for greater movement and control from the operator. These blades can come in varying forms, with 6-way and 8-way functions. The differentiation between them, are the tilt capacities, with the blades being capable of the following:

-

- 6-way blades allow for the same movement of a 4-way blade, with the addition of tilting left and right, rather than just angling. With this blade, the operator can move the blade freely from the tracks, using the joystick in the cabin.

-

- 8-way blades have the capabilities of both the 4-way and 6-way blades, as well as the ability to roll the blade.

Use this blade to achieve best results with:

- Levelling

- Back-filling

- Grading

- Land clearing

Cushion Blade

A Cushion Dozer Blade is used to transport other site equipment, rather than earthmoving materials. The attachment is often narrow and reinforced, with a heavy-duty design to assist with moving other machinery.

Use this blade to achieve best results with:

- Moving scrapers and other dozers

Further Considerations

There are some further considerations that should be made when choosing your bulldozer blade attachment. Brand specific variation in blade height and width is common, which can impact the height your dozer can reach, how much material it can carry, the distance it can travel with the material and how much control over the load your operator will have. Some brands have even introduced double-sided blades, which have the capacity to be flipped when one side has become worn down, saving money on servicing and new parts.

Before selecting your blade, refer to your jobsite, the type of material, and volume of material you’re working with.